Presidio Ultra

Speck Products

Problem

Speck was trying to successfully enter the ultra protection space which has been dominated by one competitor. The target market for this type of case included customers who wanted rugged protection and port coverage with less emphasis on slim minimal coverage. The goal was to provide at least as much drop protection and durability as competitors that have been more successful in this area.

Solution

We created a unique flexible design that provided an additional bumper for added protection when you want it and a slimmer case underneath when you don’t. The case integrated faceplate screen protection, charging port and mute button coverage, as well as a holster clip for easy storage and removal when worn on the hip

Role:

Lead Product Design Engineer - owned mechanical case components and holster assembly

Timeline:

6 months from initial concepts to mass production

Design Refinement

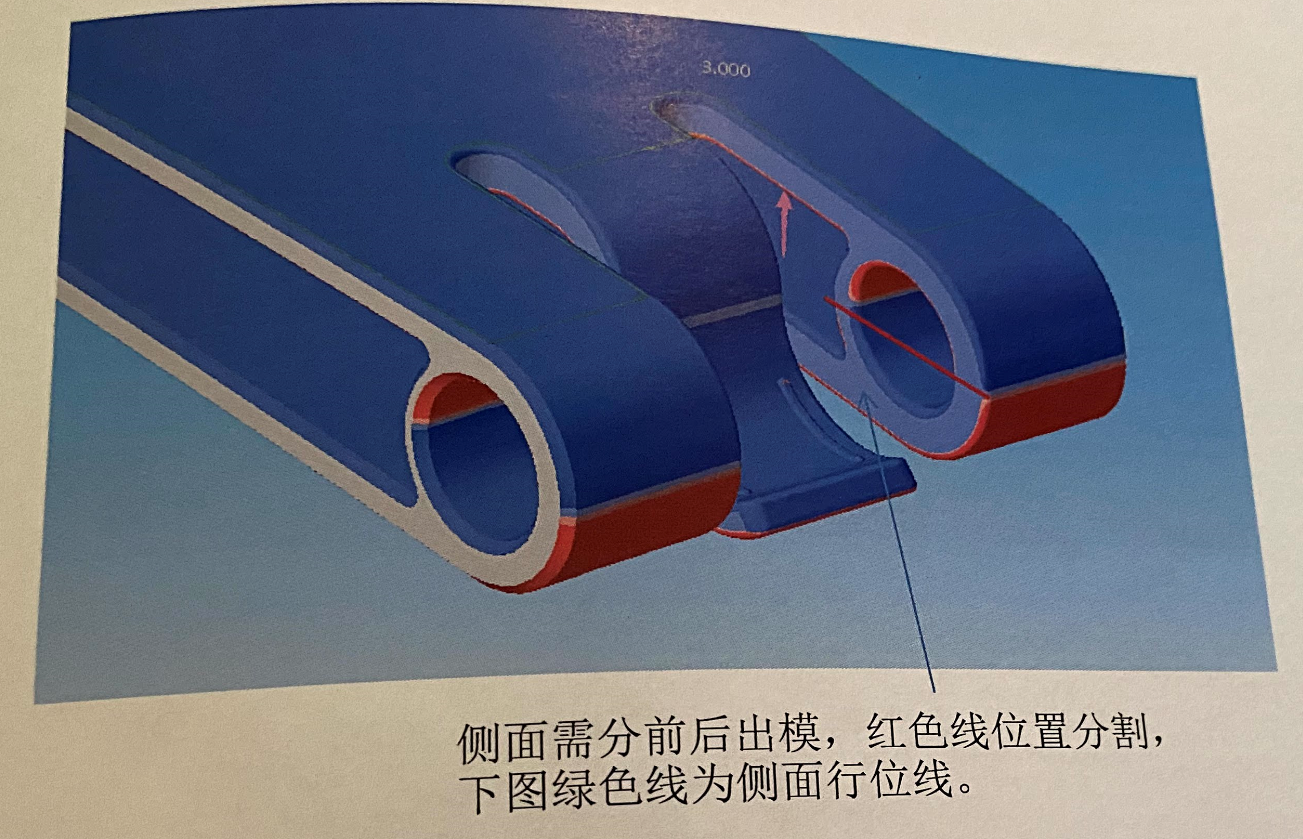

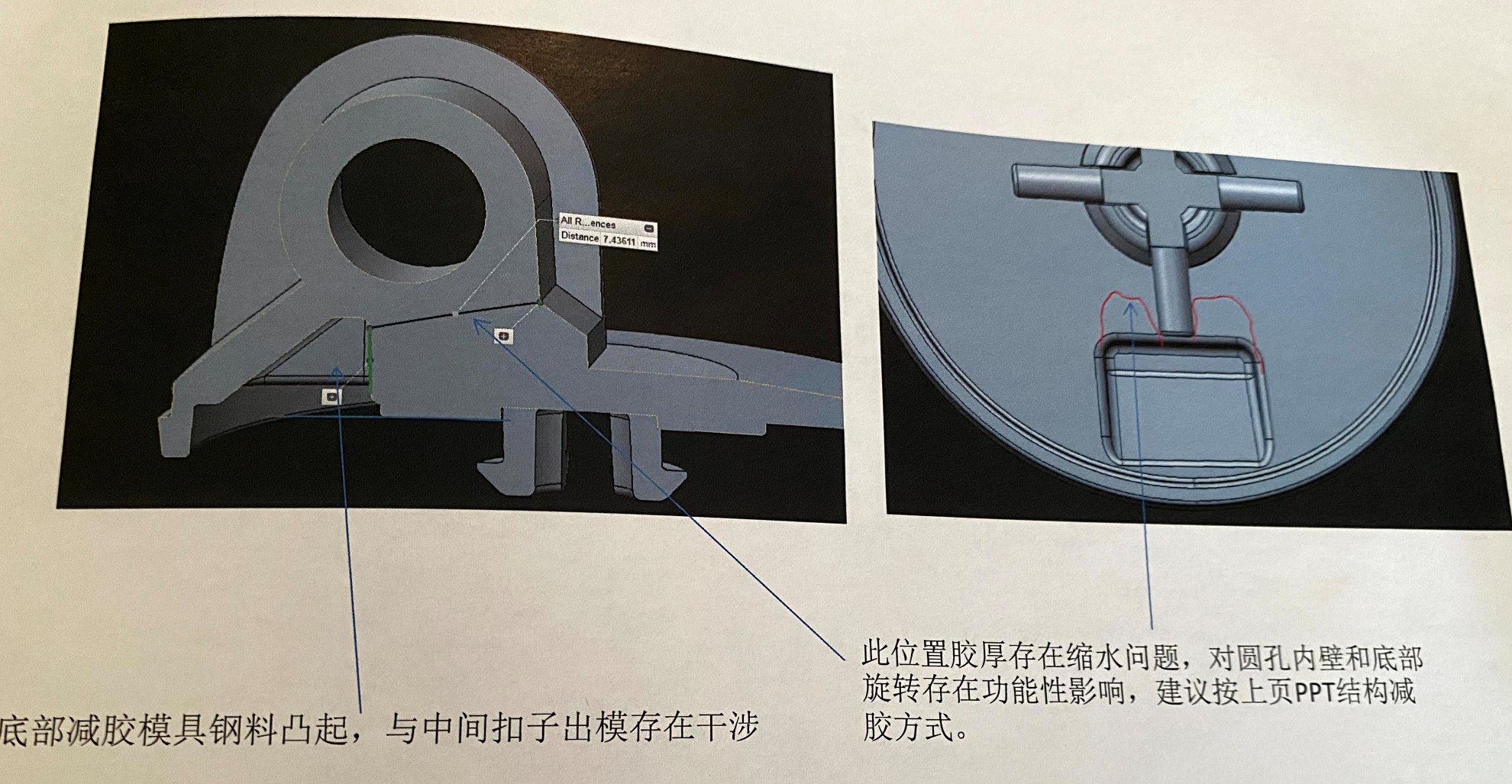

Working Through DFM Feedback From Manufacturer

Working Through Feedback from ID and Management

Tooled Parts

Challenges Met

Robust Clip

One of the most important aspects of the holster was to make the clip withstand forces that could be exerted on it by the holster catching and pulling on the clip while attached to the hip. This required product comparisons, testing, and mechanical analysis.

Unknowns

We had one previous holster to reference but there were many unknowns in terms of design changes. We considered other manufacturing methods, but the design that was executed was a lower risk option due to unknowns and the short schedule.

Ratcheting Mechanism

The holster clip had to rotate and lock into 4 positions. I designed detents on the bottom that would allow the clip to flex and click into these positions. Durability and wear had to be considered because the design was plastic to reduce cost.

Charging Port Door

The ID direction was to use a separate piece for the door which established constraints within the thickness of the case and made it difficult to design a robust functional snap.

Timeline

Once this project was approved for development we had a significantly short timeline to execute it in order to meet the next iPhone launch.

Mute Button Switch

The mute switch button was particularly challenging because the goal was to reduce its size as much as possible. The knob had to be optimized for this and also had to be snapped into the case for assembly.

Skills Demonstrated

CAD (Creo)

Master modeling

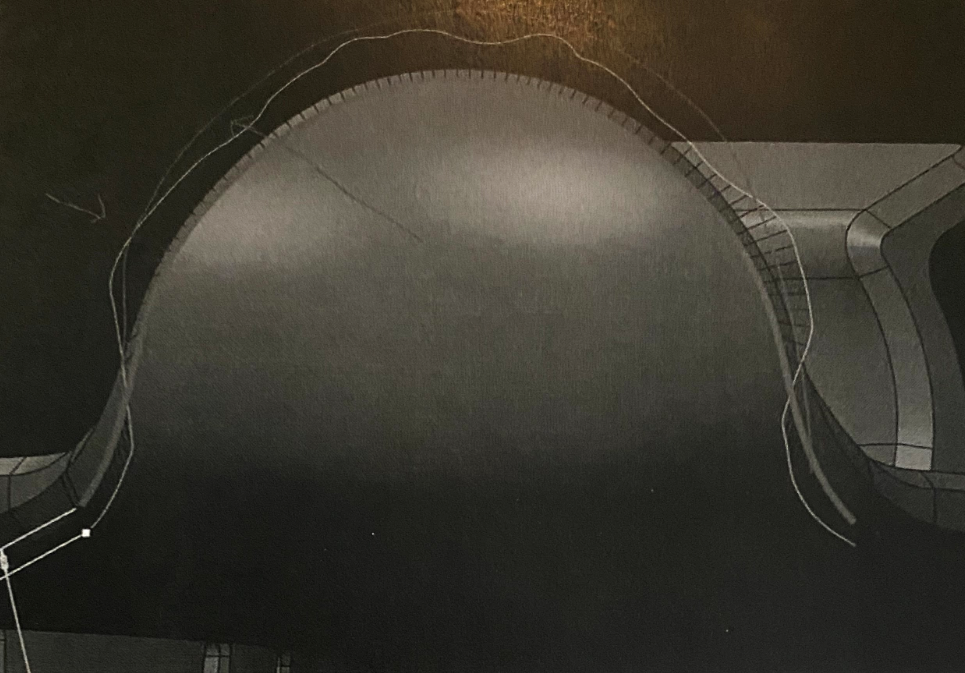

Surfacing

Sharing assembly ownership

Plastic and TPU part design

Snap design

FEA