Advanced Lift Attachment

Problem

The Studio Lift was limited by hardware and software applications to 50 lbs per arm and there was an urgent request to enable higher forces within the launch and ship date.

Solution

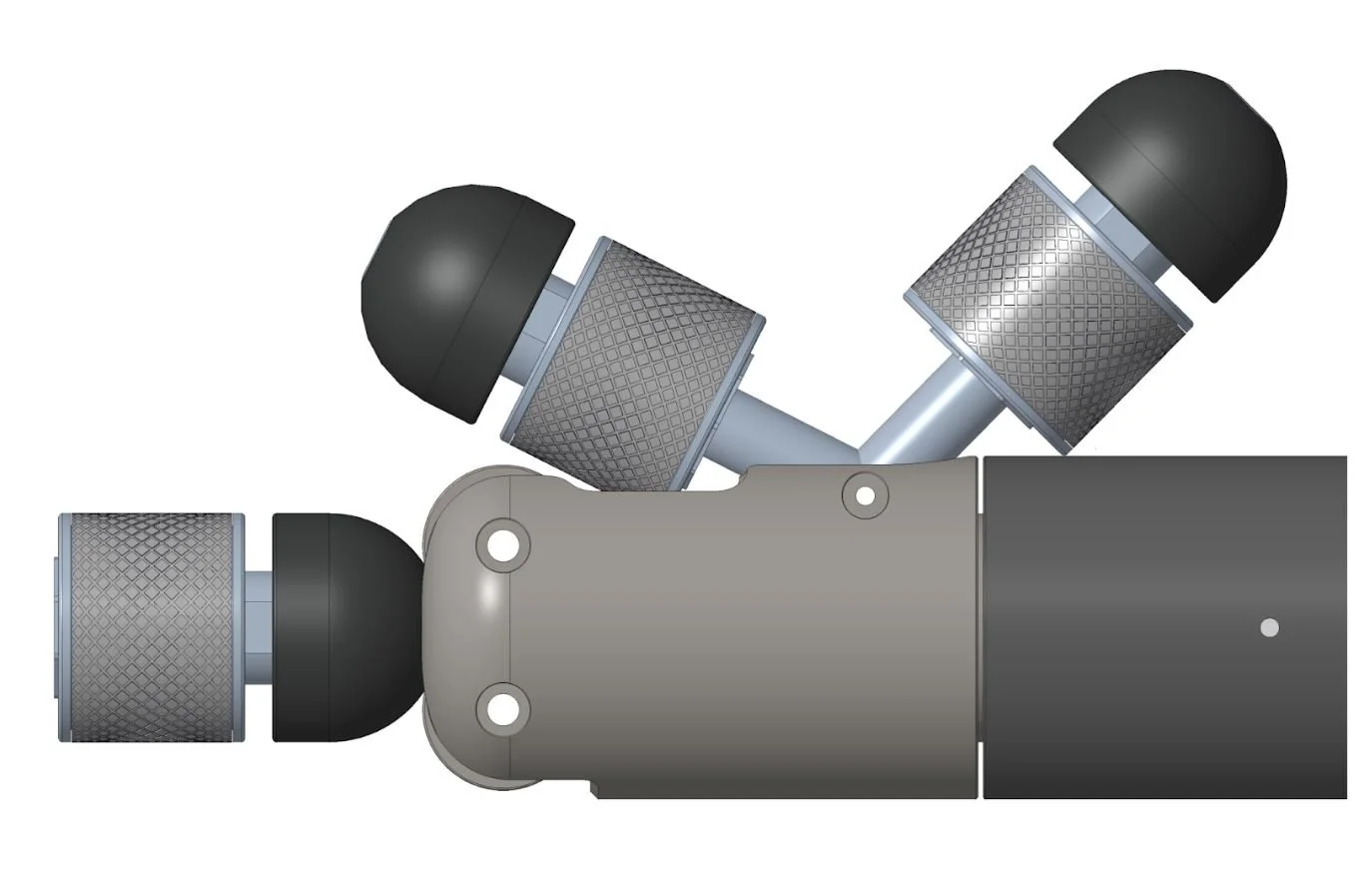

A system of accessories that attaches to the current arm and existing accessories that allows the cord to wrap through a pulley with a swivel door and connect back to the arm to double the force.

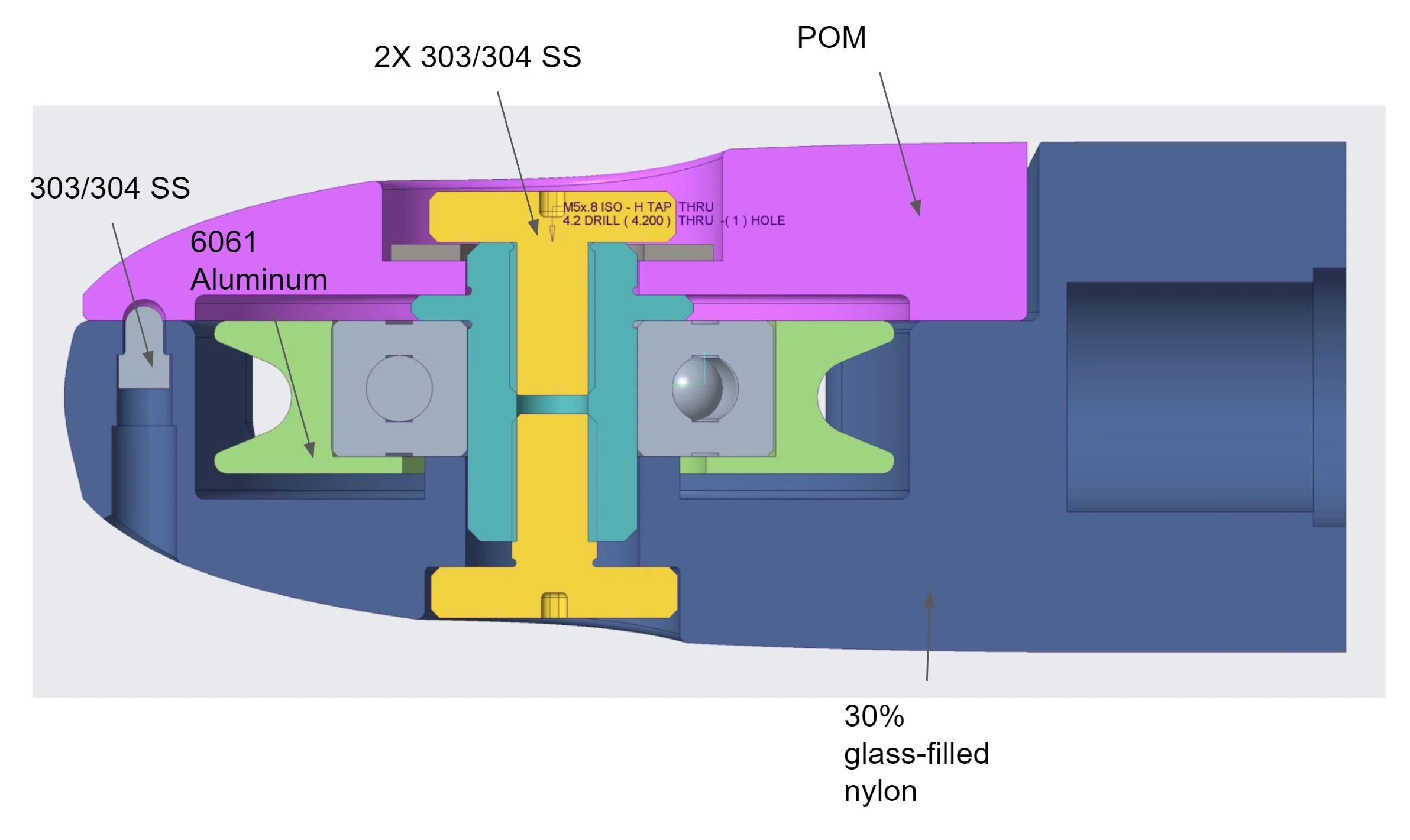

The components were a pulley assembly that would connect to our quick release mechanism and a nylon+rubber+velcro cuff that would wrap around the arm. It was critical for the pulley assembly to open for the user to attach it in-line easily, but be able to lock closed securely.

Concurrent to this project was a redesign of the arm end to integrate the connecting stud into the arm itself, which required iteration to both.

Role

Lead Design Engineer - full assembly owner

Timeline

6 months

Latch Mechanism

One of the critical challenges of the pulley design was making it a great user experience to open and close the door for attachment, while making the spring-loaded latch strong enough to withstand the forces and impact it of functional use. This required three rounds of iteration and prototyping with 3D printed and machined parts with final CMF and finish for presentation.

With integrated arm end stud

With add-on strap + stud

Challenges Faced

Timeline

Durability

Secure Locking Mechanism

Clean Aesthetics

Testing: Cycle, Jerk, Load (2.5 FoS)

Meeting evolving requirements with parallel paths

Skills Demonstrated

Time Management

Multitasking

Delegation

Mechanism Design

Surfacing

Prototyping: 3D prints through production quality CMF

Test Engineering