Problem:

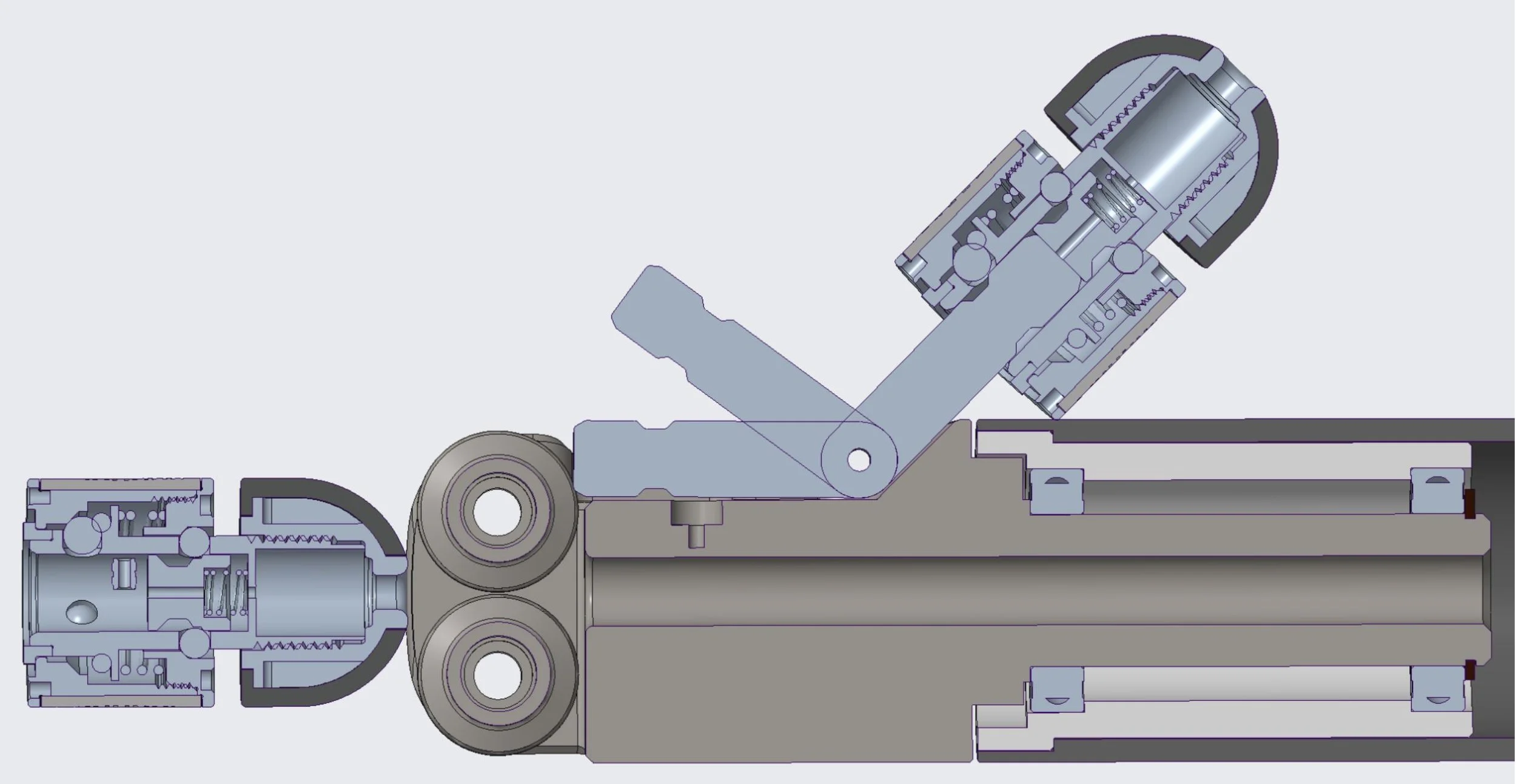

The existing arm end was too large to stow properly and would get stuck against the lift unit and/or wall it was mounted against. The cable also created visible wear against it and it was very expensive to produce.

Solution:

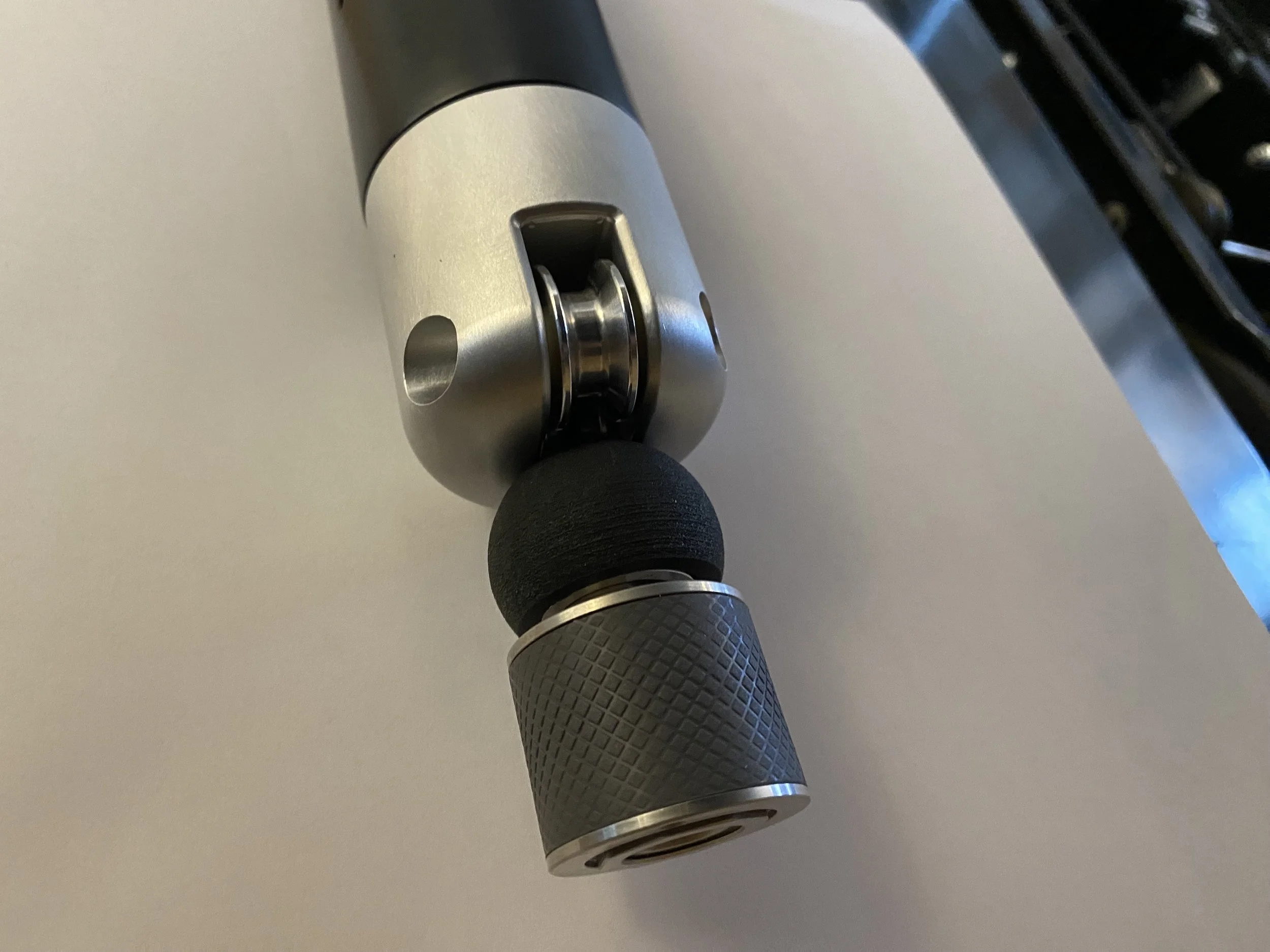

I was able to remove more than half of the components in the arm assembly with a single forged + machined aluminum piece that was small enough to fit within the diameter of the arm and significantly reduced cost and weight.

It was a challenge to have the pulleys and arm end itself to rotate smoothly within the force and range of movement of the user which required bearing and material selection, iteration and cycle testing.

The initial developments included an integrated stud that would rotate and be held into the arm end with a magnet to allow the force-doubling power of the advance Lift Attachment but it was later simplified to remove this feature and reduce cost as a smaller anodized aluminum part.

Timeline: 6 months

Role: Lead Mechanical Engineer

Challenges Faced

Space Constraints

Minimum bend radius of pulley

Wear on cord

Rotation of arm end

Competing factors and priorities

TImeline

Skills Demonstrated

CAD (Creo/Pro-E)

Testing (setup and execution)

Presentation to upper management (CEO)

Working with ID contractors

Prototyping